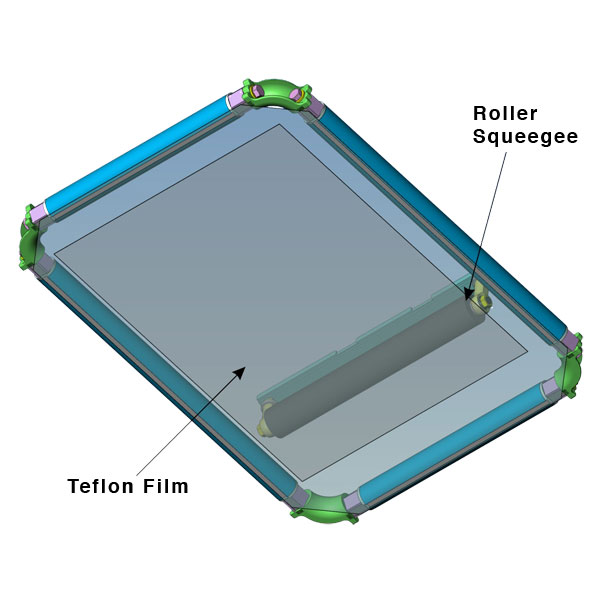

Roller Squeegee

Features:

- Eliminate Fibrillation

- Use with a lint pick-up screen

Description:

After flashing, it is entirely probable that you have fibers sticking up through the ink. Use the roller squeegee and a piece of Teflon film to flatten out the image and improve the smoothness of the print.

Use of the Roller Squeegee with Teflon film (now included) following a flash has numerous benefits. That is, the roller squeegee will provide a very smooth and uniform hand to the final product. Consider how Teflon film is used in association with a heat press. Price includes a piece of Teflon film.

Roller squeegees are available for most automatic press brands. Inquire for further pricing and information.

We all know the challenges presented by excess lint on the garments that we print on. When the catcher at the end of the dryer tells you that there's a big piece of lint on the blue screen in the letter Q, it means 30 imperfect shirts have been produced. Stopping your machine means lowering your production rates. Hence, de-linting screens are employed. Place a screen on your first head that has a light tack spray applied to it. Other tacky surfaces are also available. When the roller squeegee is used with this de-linting screen, it picks up excess lint off the garment.

Flattening Out Garments: before printing, use a flash cure at one station and then a roller squeegee at the next. This will completely flatten out the garment and get the fibers to lay down. Other Possible Uses: As an embossing tool, the Roller Squeegee can be used in association with textured surfaces applied to your screen to produce some very unique effects.

click "Read More" to see a sample comparison