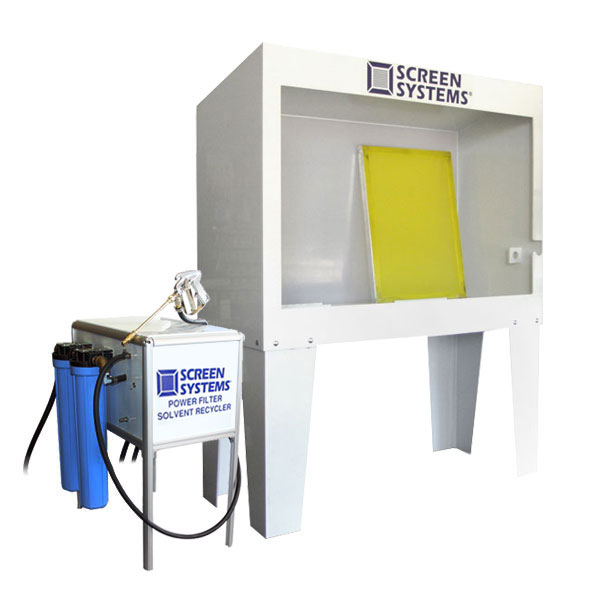

Ideal for small shops and screens too large to make automatic cleaning practical. The trigger wand controls when the spray is turned on. Uses safe, biodegradable, water soluble screen wash that is constantly filtered and recycled. The closed system means that solvent is pulled from its separate drum, and sprayed on the screen. Dirty fluid is picked up in the drain and power filtered before returning it to the drum. Rinse excess wash off with water. Attaches to the Screen Systems sink that was designed to eliminate the problems of the screen printer. The slanted roof helps solvent run to the rear instead of dripping on your just washed screen. Splash guards on the sides help keep the operator dry. The perforated double bottom keeps used wash from splashing up on a clean screen. It also helps keep a dropped screen from popping. Heavy duty 3/8" polypropylene provide years of service

The ideal combination for cleaning the ink out of your screens. The combination a 2 pump solvent recycler and a Screen Systems Washout Sink. The Screen Systems sink is totally designed for the screen printer. It features durable welded polypropylene construction of 3/8 in. and 1/2 in. poly. The perforated double bottom protects the actual sink bottom while eliminating splashes and catching any debris. The angled top allows over spray to run down to the back and not drip on your clean screen.

This is the latest advance in manual screen washing available anywhere. We feel that this is the safest system available for both the worker and the environment. The washer is a manually controlled, air powered system. This eliminates the need for explosion proof motors that might not remain that way. Air power is the safest source for powering a solvent based cleaning system.

The operator places his screen in the sink and activates the spray gun. The spray gun delivers 2500, 2550, or 2650 biodegradable cleaning solvent to screen while the operator scrubs into any ink residue with a brush. Ink is easily and quickly broken up by agitation, combined with the solvent power of Screen Systems biodegradable solvents to completely clean any screen in a few minutes.

After solvent drains from the screen, it flows into the drain and is pumped through a series of two filters. This dual filtration design removes particles down to one micron in size from the solvent, effectively removing almost all pigment. Only used filters need to be properly disposed of. Once filtered, the solvent is returned to the reservoir for reuse. The cabinet and most components are made of welded polypropylene. This makes the unit light weight and almost indestructible. The entire system uses no electricity, it is powered entirely by air. The Pump Station requires a clean air supply which should not exceed 100 psi or 10 c.f.m.

The system allows the effective multiple use of biodegradable solvents while keeping costs below that of standard solvents.

Available in one and two pump versions. The one pump version delivers about 4 gallons per minute, with a slight pulsing action to the spray. The two pump version delivers a steady stream of about 8 gallons per minute.